Hope Technology has been making bottom brackets for most of our 30 year existence. As with all our products, we saw a better way of doing things, so we went out and made our own. Things were a little simpler in the beginning though. There truly was only one real mountain bike bottom bracket standard. Square taper ruled the roost and our titanium axled version was king.

Unsung hero

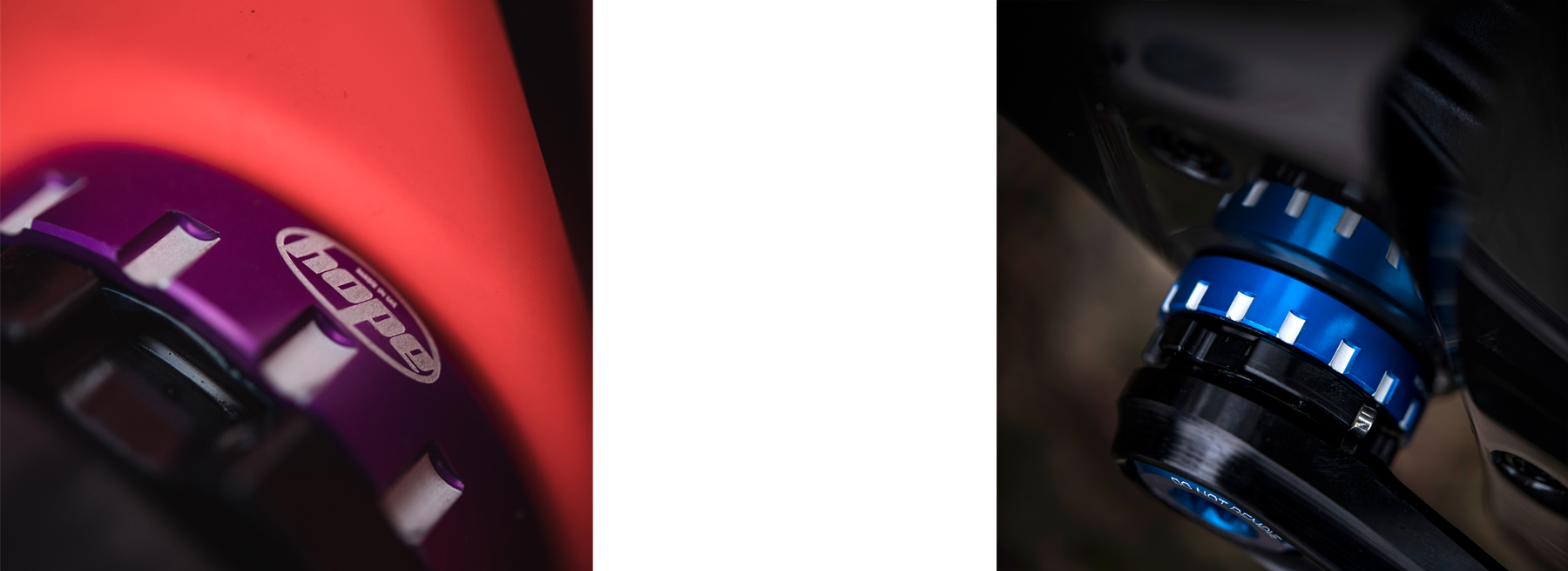

Times moved on, though, and with them came external bearings, then press fit and a multitude of different axle sizes. With each new “standard”, we took to the drawing board and applied the Hope watchwords of performance and reliability. Let’s face it, BBs have a tough life in the UK. They are frequently submerged in water, slop and grit; often hosed clean. The bottom bracket is the centre of the bike. It allows us to convert leg power into forward motion. We expect our cranks to spin as efficiently as possible, regardless of conditions. It’s the unsung hero of the bike – barely visible, but working hard every ride. That’s why there are few things that you can be sure of, regardless of which Hope bottom bracket you need:

The best sealed stainless steel cartridge bearings available – specifically designed for the rigours of riding

Additional outer labyrinth seals to further protect bearings*

Precision engineering and tolerances

Hope Technology warranty and service support

*not applicable to PF41 30mm axle BB, due to design limitations

The durable choice

While no bottom bracket is truly fit and forget, regardless of which Hope bottom bracket you need, you can be sure that it will keep on trucking through the worst conditions, way beyond the life of a stock BB. When it is finally time for a bearing change, there is no wasteful disposable of the cups – just a simple swapping out of the cartridge bearings.

Press Fit headaches...

Press Fit has developed something of a reputation, with many riders complaining of creaking and poor longevity. There are a few extra design features that set our bottom brackets apart from the crowd. For example, our Press Fit options use a threaded centre tube* where design allows. This has a number of advantages – it ensures that the two bearings are perfectly aligned (a common cause of creaking and premature wear is bearing misalignment), brings enhanced rigidity to the system and helps protect the bearing from any moisture build up in the frame.

DUB

Back in 2018, SRAM introduced DUB – using a 29mm crankset axle. A dub converter is available for all of our 30mm bottom bracket options.

Standards

Now, whatever your axle size or bottom bracket standard, there is almost certainly a Hope Technology bottom bracket to fit your requirements. At last count, we have 32 options available across 5 bottom bracket shell types, 13 frame shell widths and three crankset axle diameters. Everything from road bikes to fat bikes are covered. If all that feels a little mind-boggling, you’ll be glad to know that we have a handy compatibility guide to work out exactly which BB your bike and crankset needs.

.jpg)

The bottom line

Whatever bottom bracket your bike needs, Hope Technology offers the durable, reliable option for UK conditions.